Plexiglass cover magnetically attached to mount LED lighting on the ceiling.

Plexiglas cover magnetically attached

Problem: I wanted to use the advantages of LED lighting in our living room. LED strips should be installed along a suspended ceiling structure. Unfortunately, there are not many possible solutions on the market yet. So I planned and carried out this myself.

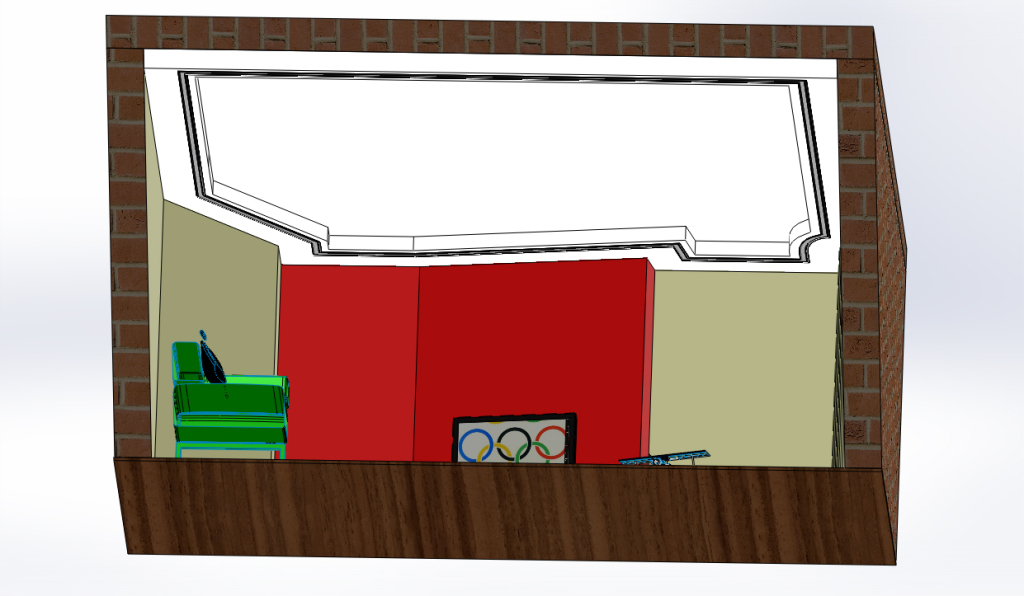

Here our living room and the schematic representation of the lighting bar are shown in a CAD drawing.

The surrounding lighting strip can be seen in the ceiling construction (white area). This is a total of 17.5 m long.

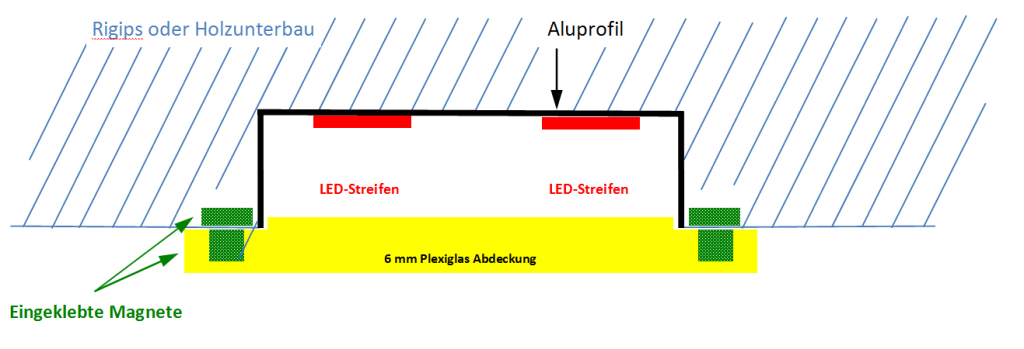

I worked an aluminum profile into the Rigips substructure. The LED strips will later be glued into this aluminum rail.

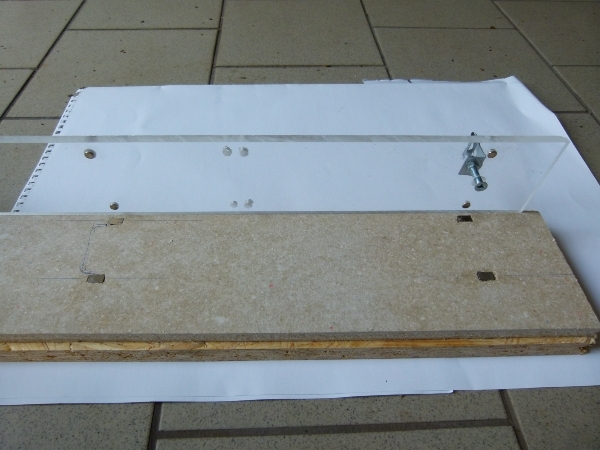

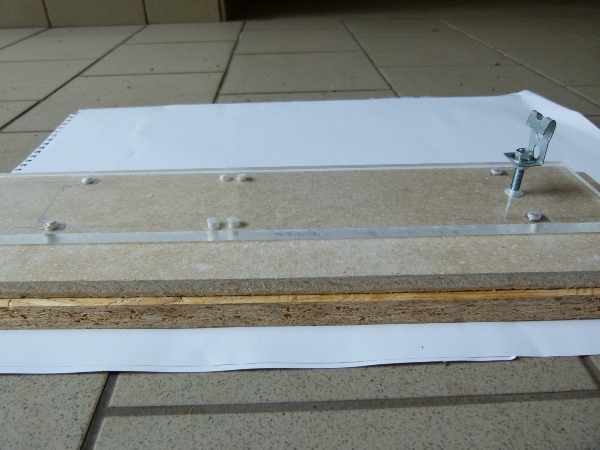

For the cover I use 6 mm satined Plexiglas strips, which are attached to the Rigips substructure by means of blockmagnets and discmagnets in the Plexiglas.

Why is the magnet solution so ingenious?

Plexiglass has a thermal expansion that should not be underestimated (approx. 1.8 mm / m at a temperature of 25 ° C). With this combination of magnets, the plexiglass can expand. No magnetic adhesion is lost.

The magnets are arranged on both sides at a distance of approx. 25 cm and are glued into the substructure with epoxy glue and into the plexiglass with superglue. About 150 disc and 150 blockmagnets were used in this project.

In view of the specified holding forces of the magnets, the selection seems overdimensioned. Practical attempts revoke this. Not all magnets are 100% on top of each other. The force is applied vertically and laterally. The weight of the plexiglass bar must be borne. It shouldn’t fall down when vacuuming.