Today’s application is a magnetic cover for the exhaust system of a motorcycle.

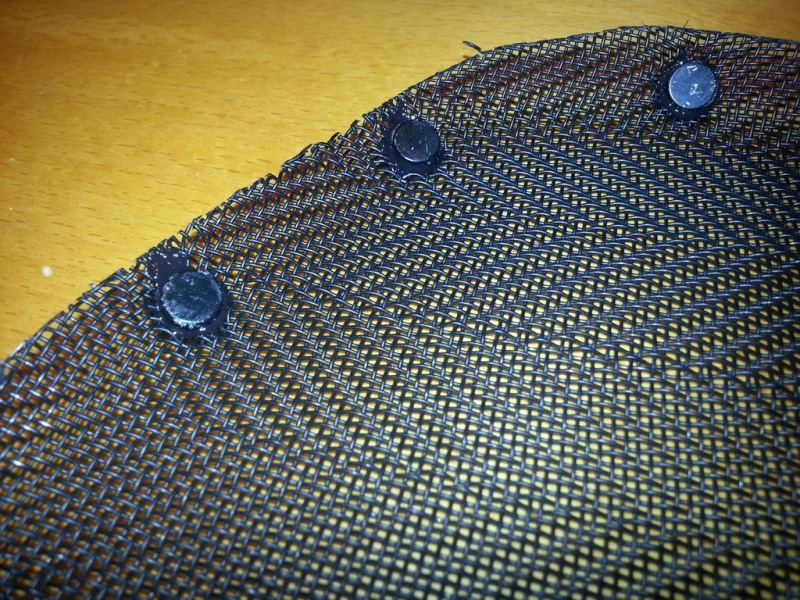

This consists of a metallic grid material.

Neodymium magnets are known for their incredible power, but they are not very heat-resistant. The maximum temperature is 80 ° C.

Our customer is enthusiastic about his application and is working on improving this application with samarium-cobalt magnets!

Magnetic cover for an exhaust system

Hello Magnet Shop Team!

I used the magnets to fix grid material to two covers of a motorcycle exhaust system.

Fixation points of the magnets were deep-drawn in the grid material. The magnets were glued in using heat-resistant silicone. The grille attached to the cover from the inside.

Magnets hold the grid on the steel.

This worked very well in the beginning.

When buying the magnets, I opted for the epoxy variant for weather protection.

The place of use of the magnets is of course extremely unfavorable with regard to the effects on them. In my opinion, heat, cold and moisture are a „tough test“.

I will definitely add samarium-cobalt magnets to my application, as these are very heat-resistant and have the desired adhesive force.

Samarium-cobalt magnets (SmCo), like neodymium magnets, are rare earth magnets. There are two different types of alloys, SmCo5 with 36% samarium content and Sm2Co17 with 25% samarium content, which in addition to cobalt also contains iron (up to 18%) and copper (up to 12%).

SmCo magnets are very temperature resistant. The maximum operating temperature is 250 ° C (SmCo5) and 350 ° C (Sm2Co17).

The samarium cobalt magnets are quite resistant to demagnetizing magnetic fields and do not need to be protected against corrosion.